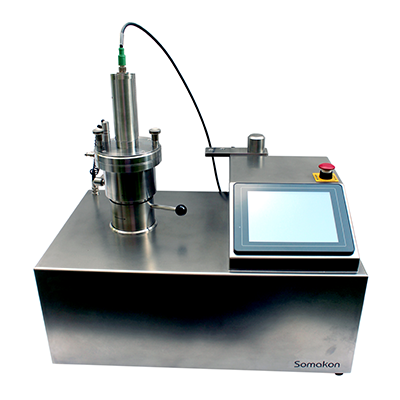

Sectors such as the food, chemical and pharmaceutical industries are placing ever higher demands on the flexible usability of their laboratory machines. Therefore, manufacturers are challenged to also question and optimize proven solutions. The laboratory mixer of the MP-LB series is an innovative, modular development tool that significantly improves the efficiency of the transfer from laboratory to production scale and thus helps to save costs.

For more than ten years, Somakon Verfahrenstechnik has been focusing on the problems of mixing and granulating on a laboratory scale.

Our laboratory mixers are in high demand in the research and development departments of well-known industrial users. Thanks to their modular design, they can be individually adapted to a wide variety of tasks in everyday development work. By changing the tools and varying the parameters such as speed and time, users can simulate various production mixers.

Somakon mixers are therefore highly valued laboratory equipment in the chemical industry and for producers of aromas, pharmaceuticals and pesticides.

In various stages of expansion, up to pilot plant level, they are used for the production of samples, products and standards under the aspect of production-related manufacturing.

They support application technology and research in solving many process questions and are used in quality control, for example for raw materials in incoming goods.

The core of this mixer concept is the modular design. MP-LB stands for “MultiPurpose Laboratory Batch”. In addition to actual mixing, this universal mixer can also be used for granulating, pelletizing, emulsifying, suspending, kneading, loading, comminuting or drying, depending on the expansion stage. Depending on the process steps to be carried out, the laboratory mixer is equipped with other tools. In addition, Somakon offers container sizes from 0.5 to 14 liters. The exchange of the containers takes only a few seconds.

In the basic equipment, the mixer is equipped with a touch screen, which allows manual operation of the mixer with timer control. A scraper acting from above and running against the direction of rotation of the main motor, as well as a display of the product temperature can be integrated into the MP basic unit. Modules such as, among others, a vacuum pump station, a temperature control unit, sensor units (temperature, pH, conductivity), and a data logger enable simple vacuum and temperature control tasks.

For those users who prefer a fully automatic control system for customized automation, a version with a separate PLC is available, which then enables entire program sequences with integrated data acquisition.

Mixing

Due to the tool variations, mixing tasks from gentle to aggressive are possible. Thus, various mixer types such as free-fall, plowshare, auger belt, Nauta and many more mixers can be simulated.

Loading

Here, carriers that have capillary cavities are loaded with a liquid. A typical process in the production of detergents is the loading of soda with liquid surfactants.

Coating

Coating processes can also be carried out by atomizing or slowly adding suitable liquids using, for example, a small two-substance nozzle (crop protection agents).

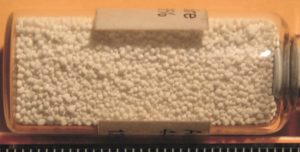

Granulating/Pelletizing

First and foremost, wet granulation is carried out with the mixer. Liquid is introduced through the lid with a single- or dual-substance nozzle.

Speed and die variations can influence particle size and particle hardness. With modified process parameters, pelletizing and subsequent drying can also be performed with an identical die configuration.

Drying

Alternating vacuum and aeration on the one hand and tempering via the double jacket on the other, gentle drying processes are possible.

Emulsifying / Dispersing/Kneading

By changing the tools, the Somakon mixer or granulator can be configured into a process plant for semi-solid products within a very short time. The tool, specially designed for this occasion, allows emulsification operations from low to high viscosity and achieves the same dispersities as the classic production-scale rotor-stator process plants. In addition, it allows the function of a knife kneader.

The laboratory mixers of the MP-LB series allow conclusions to be drawn about the quality of the end product, which can be manufactured on various production lines, even with small sample quantities (50g). Many questions can thus be clarified at a very early stage of development. With this mixer, the user can significantly shorten the time required from the development of a product to standardized production.

Tank volume: 0.5 / 1.0 / 2.5 / 5.0 / 14.0 liters

Main motor: 1,5 [kW / AC]

Speed: 150 – 2000 [rpm]

counter-rotator: 5-50 [rpm]

Dimensions*: Width: 65 / Depth: 40 / Height: 30 [cm]

Operating voltage: 230V / 50 Hz

Parts in contact with the product: AISI 316 stainless steel

*without mixing bowl